|

|

PDF LT3652HV Data sheet ( Hoja de datos )

| Número de pieza | LT3652HV | |

| Descripción | Power Tracking 2A Battery Charger | |

| Fabricantes | Linear Technology | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de LT3652HV (archivo pdf) en la parte inferior de esta página. Total 24 Páginas | ||

|

No Preview Available !

www.DataSheet4U.com

LT3652HV

Power Tracking 2A Battery

Charger

FEATURES

n Input Supply Voltage Regulation Loop for Peak

Power Tracking in (MPPT) Solar Applications

n Wide Input Voltage Range: 4.95V to 34V (40V Abs Max)

n Programmable Charge Rate Up to 2A

n User Selectable Termination: C/10 or On-Board

Termination Timer

n Resistor Programmable Float Voltage Up to 18V

Accommodates 4-Cell Li-Ion/Polymer, 5-Cell

LiFePO4, Lead-Acid Chemistries

n Parallelable for Higher Output Current

n 1MHz Fixed Frequency

n 0.5% Float Voltage Reference Accuracy

n 5% Charge Current Accuracy

n 2.5% C/10 Detection Accuracy

n Binary-Coded Open-Collector Status Pins

APPLICATIONS

n Solar Powered Applications

n Remote Monitoring Stations

n Portable Handheld Instruments

n 12V to 24V Automotive Systems

n Battery Charging from Current Limited Adapter

DESCRIPTION

The LT®3652HV is a complete monolithic step-down bat-

tery charger that operates over a 4.95V to 34V input range.

The LT3652HV provides a constant-current/constant-voltage

charge characteristic, with maximum charge current

externally programmable up to 2A. The charger employs

a 3.3V float voltage feedback reference, so any desired

battery float voltage up to 18V can be programmed with a

resistor divider.

The LT3652HV employs an input voltage regulation loop,

which reduces charge current if the input voltage falls below

a programmed level, set with a resistor divider. When the

LT3652HV is powered by a solar panel, the input regulation

loop is used to maintain the panel at peak output power.

The LT3652HV can be configured to terminate charging when

charge current falls below 1/10 of the programmed maximum

(C/10). Once charging is terminated, the LT3652HV enters a

low-current (85μA) standby mode. An auto-recharge feature

starts a new charging cycle if the battery voltage falls 2.5%

below the programmed float voltage. The LT3652HV also

contains a programmable safety timer, used to terminate

charging after a desired time is reached. This allows top-off

charging at currents less than C/10.

L, LT, LTC, LTM, Linear Technology and the Linear logo are registered trademarks and

PowerPath is a trademark of Linear Technology Corporation. All other trademarks are the

property of their respective owners.

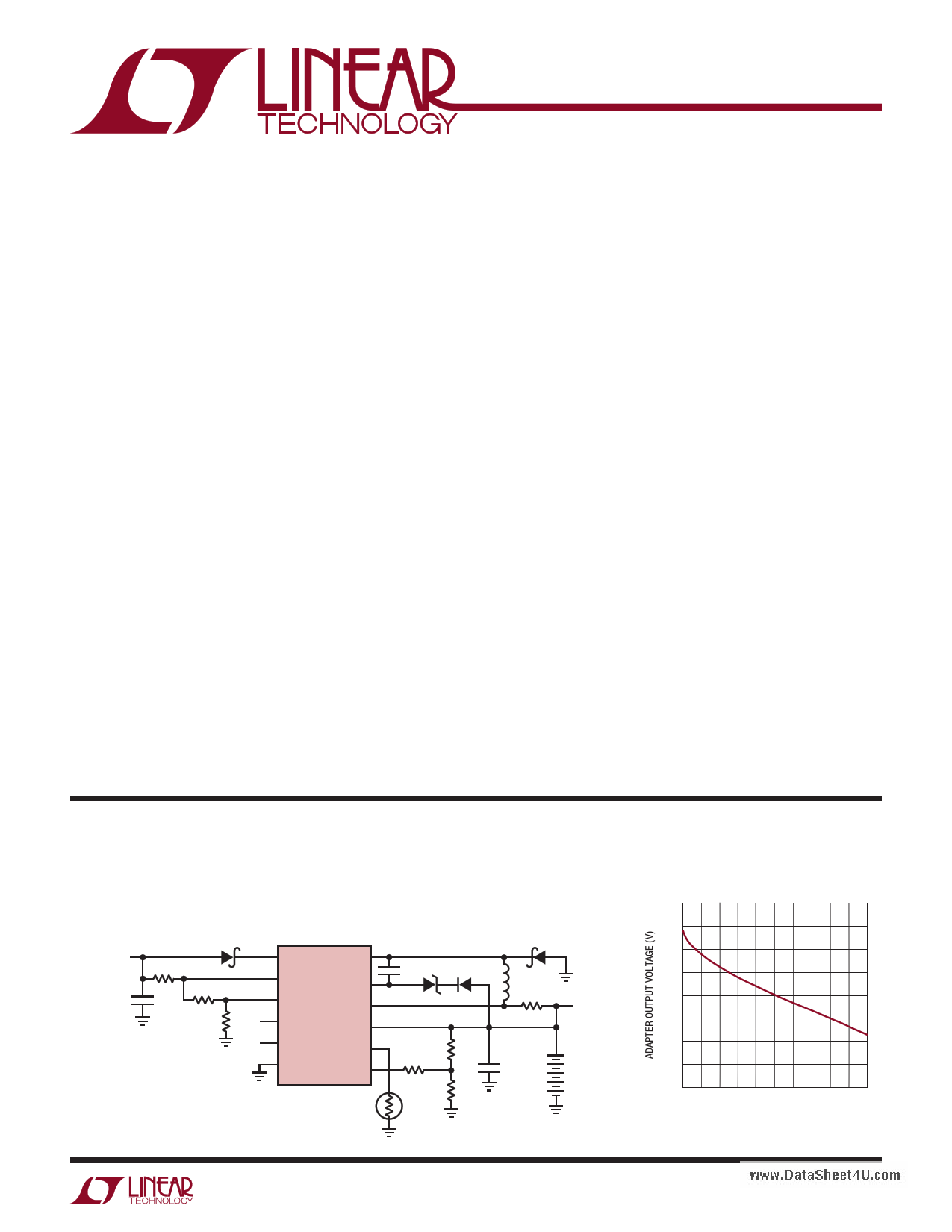

TYPICAL APPLICATION

VIN_REG Loop Servos Maximum Charge Current to Prevent AC Adapter Output from

Drooping Lower Than 24V 5-Cell LiFePO4 Charger (18V at 1.5A) with C/10 Termination

Powered by Inexpensive 24VDC/1A Unregulated Wall Adapter.

AC ADAPTER

INPUT

24VDC AT 1A

MBRS340

750k

10μF

44.2k

51.1k

VIN SW

LT3652HV

VIN_REG

BOOST

SHDN

SENSE

CHRG

BAT

FAULT

NTC

TIMER

VFB

3652 TA01a

1μF 10V 1N4148

D3

MBRS340

20μH

0.068

SYSTEM

LOAD

127k

665k

R1

10K

B = 3380

150k

+

10μF

5-Cell LiFePO4 PACK

(18V FLOAT)

1A/24VDC Unregulated Adapter

I vs V Characteristic

36

33

30

27

24

21

18

15

12

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

ADAPTER OUTPUT CURRENT (A)

3652 TA01b

3652hvf

1

1 page

www.DataSheet4U.com

LT3652HV

TYPICAL PERFORMANCE CHARACTERISTICS TJ = 25°C, unless otherwise noted.

VIN_REG Threshold

vs Temperature: ICHG at 50%

2.720

2.715

2.710

2.705

2.700

2.695

2.690

2.685

2.680

–50 –25

0 25 50 75

TEMPERATURE (°C)

100 125

3652 G01

VFB Reference Voltage

vs Temperature

3.304

3.302

3.300

3.298

3.296

–50 –25

0 25 50 75

TEMPERATURE (°C)

100 125

3652 G01a

VIN Standby Mode Current

vs Temperature

100

95

90

85

80

75

70

65

–50

–25 0 25 50

TEMPERATURE (°C)

75 100

3652 G02

Switch Drive (ISW/IBOOST)

vs Switch Current

36

33

30

27

24

21

18

15

12

9

6

3

0

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

SWITCH CURRENT (A)

3652 G03

Switch Forward Drop (VIN – VSW)

vs Temperature

480

ISW = 2A

460

440

420

400

380

360

340

320

–50 –25

0 25 50 75

TEMPERATURE (°C)

100 125

3652 G04

CC/CV Charging; SENSE Pin Bias

Current vs VSENSE

100

VBAT = VBAT(PRE)

50

0

–50 VBAT = VBAT(FLT)

–100

–150

–200

–250

–300

–350

0 0.5 1 1.5 2 2.5

VSENSE (V)

3652 G05

C/10 Threshold (VSENSE–VBAT)

vs Temperature

12

11

10

9

8

–50 –25

0 25 50 75

TEMPERATURE (°C)

100 125

3652 G06

3652hvf

5

5 Page

www.DataSheet4U.com

LT3652HV

APPLICATIONS INFORMATION

stant-current (CC) mode, which corresponds to 100mV

across RSENSE. The ITH voltage is pulled down to reduce

this maximum charge current should the voltage on the

VIN_REG pin falls below 2.7V (VIN_REG(TH)) or the die tem-

perature approaches 125°C.

If the voltage on the VFB pin is below 2.3V (VFB(PRE)),

the LT3652HV engages precondition mode. During the

precondition interval, the charger continues to operate in

constant-current mode, but the maximum charge current

is reduced to 15% of the maximum programmed value

as set by RSENSE.

When the charger output voltage approaches the float volt-

age, or the voltage on the VFB pin approaches 3.3V (VFB(FLT)),

the charger transitions into constant-voltage (CV) mode

and charge current is reduced from the maximum value.

As this occurs, the ITH voltage falls from the limit clamp

and servos to lower voltages. The IC monitors the ITH volt-

age as it is reduced, and detection of C/10 charge current

is achieved when ITH = 0.1V. If the charger is configured

for C/10 termination, this threshold is used to terminate

the charge cycle. Once the charge cycle is terminated,

the CHRG status pin becomes high-impedance and the

charger enters low-current standby mode.

The LT3652HV contains an internal charge cycle timer that

terminates a successful charge cycle after a programmed

amount of time. This timer is typically programmed to

achieve end-of-cycle (EOC) in 3 hours, but can be con-

figured for any amount of time by setting an appropriate

timing capacitor value (CTIMER). When timer termination

is used, the charge cycle does not terminate when C/10

is achieved. Because the CHRG status pin responds to

the C/10 current level, the IC will indicate a fully-charged

battery status, but the charger continues to source low

currents into the battery until the programmed EOC time

has elapsed, at which time the charge cycle will terminate.

At EOC when the charging cycle terminates, if the battery did

not achieve at least 97.5% of the full float voltage, charging

is deemed unsuccessful, the LT3652HV re-initiates, and

charging continues for another full timer cycle.

Use of the timer function also enables bad-battery detec-

tion. This fault condition is achieved if the battery does

not respond to preconditioning, such that the charger

remains in (or enters) precondition mode after 1/8th of

the programmed charge cycle time. A bad battery fault

halts the charging cycle, the CHRG status pin goes high-

impedance, and the FAULT pin is pulled low.

When the LT3652HV terminates a charging cycle, whether

through C/10 detection or by reaching timer EOC, the

average current mode analog loop remains active, but

the internal float voltage reference is reduced by 2.5%.

Because the voltage on a successfully charged battery is

at the full float voltage, the voltage error amp detects an

over-voltage condition and ITH is pulled low. When the

voltage error amp output drops below 0.3V, the IC enters

standby mode, where most of the internal circuitry is dis-

abled, and the VIN bias current is reduced to 85μA. When

the voltage on the VFB pin drops below the reduced float

reference level, the output of the voltage error amp will

climb, at which point the IC comes out of standby mode

and a new charging cycle is initiated.

VIN Input Supply

The LT3652HV is biased through a reverse-current block-

ing element from the charger input supply to the VIN pin.

This supply provides large switched currents, so a high-

quality, low ESR decoupling capacitor is recommended

to minimize voltage glitches on VIN. The VIN decoupling

capacitor (CVIN) absorbs all input switching ripple current

in the charger, so it must have an adequate ripple current

rating. RMS ripple current (ICVIN(RMS)) is:

ICVIN(RMS) ≅ ICHG(MAX) • (VBAT / VIN)•([VIN / VBAT] – 1)1/2,

where ICHG(MAX) is the maximum average charge current

(100mV/RSENSE). The above relation has a maximum at

VIN = 2 • VBAT, where:

ICVIN(RMS) = ICHG(MAX)/2.

The simple worst-case of ½ • ICHG(MAX) is commonly

used for design.

3652hvf

11

11 Page | ||

| Páginas | Total 24 Páginas | |

| PDF Descargar | [ Datasheet LT3652HV.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| LT3652HV | Power Tracking 2A Battery Charger | Linear Technology |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |