|

|

PDF IW1810 Data sheet ( Hoja de datos )

| Número de pieza | IW1810 | |

| Descripción | Off-Line Digital Green-Mode PWM Controller | |

| Fabricantes | iWatt | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de IW1810 (archivo pdf) en la parte inferior de esta página. Total 13 Páginas | ||

|

No Preview Available !

iW1810

Off-Line Digital Green-Mode PWM Controller

Integrated with Power BJT

1.0 Features

●● Primary-side feedback eliminates opto-isolators and

simplifies design

●● Internal 800-V bipolar junction transistor (BJT)

●● 64kHz PWM switching frequency

●● No-load power consumption < 100mW at 230Vac with

typical application circuit

●● Adaptive multi-mode PWM/PFM control improves

efficiency

●● Quasi-resonant operation for highest overall efficiency

●● EZ-EMI® design to easily meet global EMI standards

●● Dynamic BJT base drive current control

●● Very tight constant voltage and constant current

regulation with primary-side-only feedback

●● No external compensation components required

●● Complies with EPA 2.0 energy-efficiency specifications

with ample margin

●● Low start-up current (8μA typical)

●● Built-in soft start

●● Built-in short circuit protection and output overvoltage

protection

●● Built-in current sense resistor short circuit protection

●● No audible noise over entire operating range

L

2.0 Description

The iW1810 is a high performance AC/DC power supply

control device which uses digital control technology to

build peak current mode PWM flyback power supplies.

This device includes an internal power BJT and operates in

quasi-resonant mode to provide high efficiency along with a

number of key built-in protection features while minimizing

the external component count, simplifying EMI design and

lowering the total bill of material cost. The iW1810 removes

the need for secondary feedback circuitry while achieving

excellent line and load regulation. It also eliminates the

need for loop compensation components while maintaining

stability over all operating conditions. Pulse-by-pulse

waveform analysis allows for a loop response that is much

faster than traditional solutions, resulting in improved

dynamic load response. The built-in power limit function

enables optimized transformer design in universal off-line

applications and allows for a wide input voltage range.

iWatt’s innovative proprietary technology ensures that

power supplies built with iW1810 can achieve both highest

average efficiency and less than 100 mW no-load power

consumption in a compact form factor.

3.0 Applications

●● Low-power AC/DC power supply for smart meters, motor

control and industrial applications

●● Linear AC/DC replacement

●● Low-power AC/DC LED driver

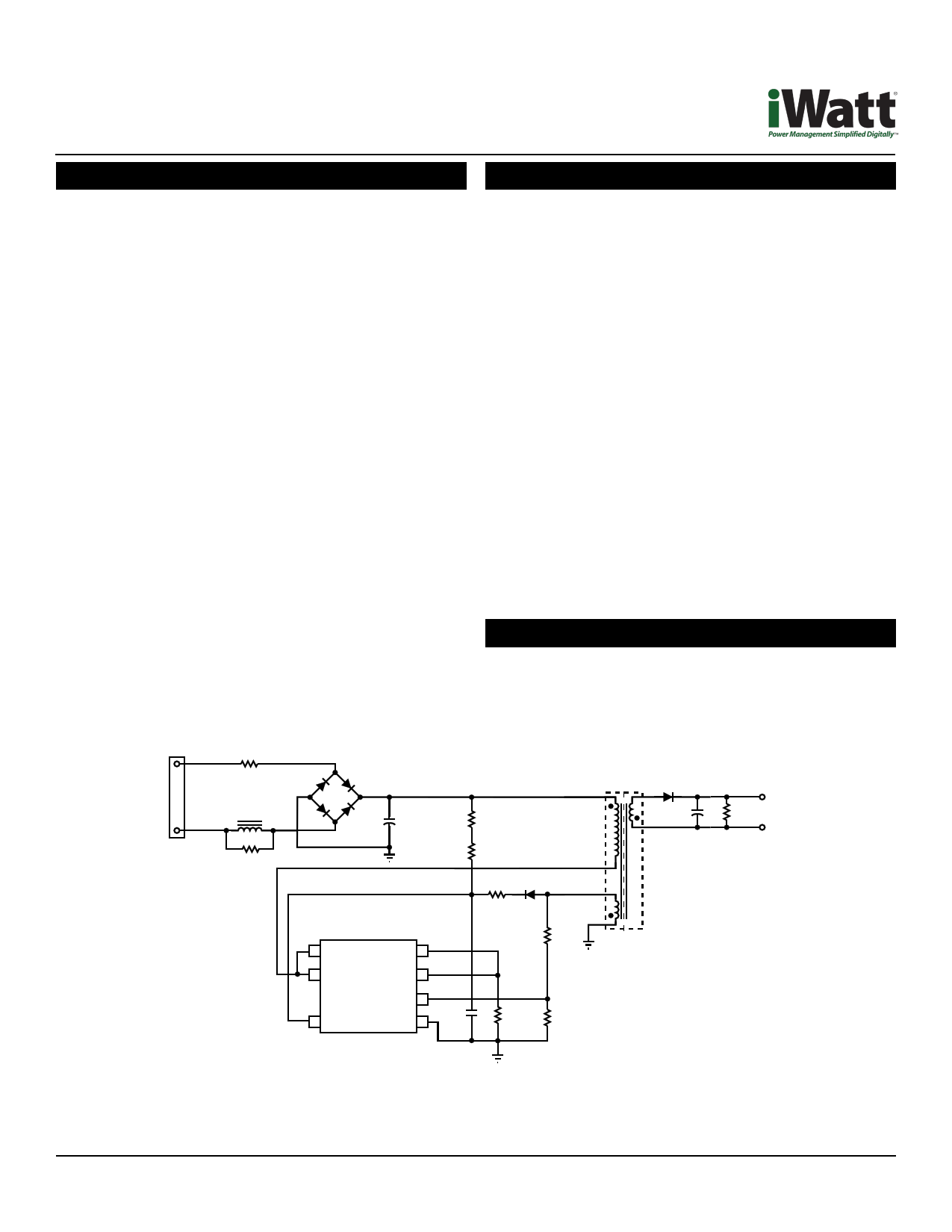

+

N

+ VOUT

GND

1C

U1

iW1810

E8

2C

4 VCC

ISENSE 7

VSENSE 6

GND 5

WARNING:

Figure 3.1: iW1810 Typical Application Circuit

The iW1810 is intended for high voltage AC/DC offline applications. Contact with live high voltage offline circuits

or improper use of components may cause lethal or life threatening injuries or property damage. Only qualified

professionals with safety training and proper precaution should operate with high voltage offline circuits.

Rev. 1.2

iW1810

April 6, 2012

Page 1

1 page

iW1810

Off-Line Digital Green-Mode PWM Controller

Integrated with Power BJT

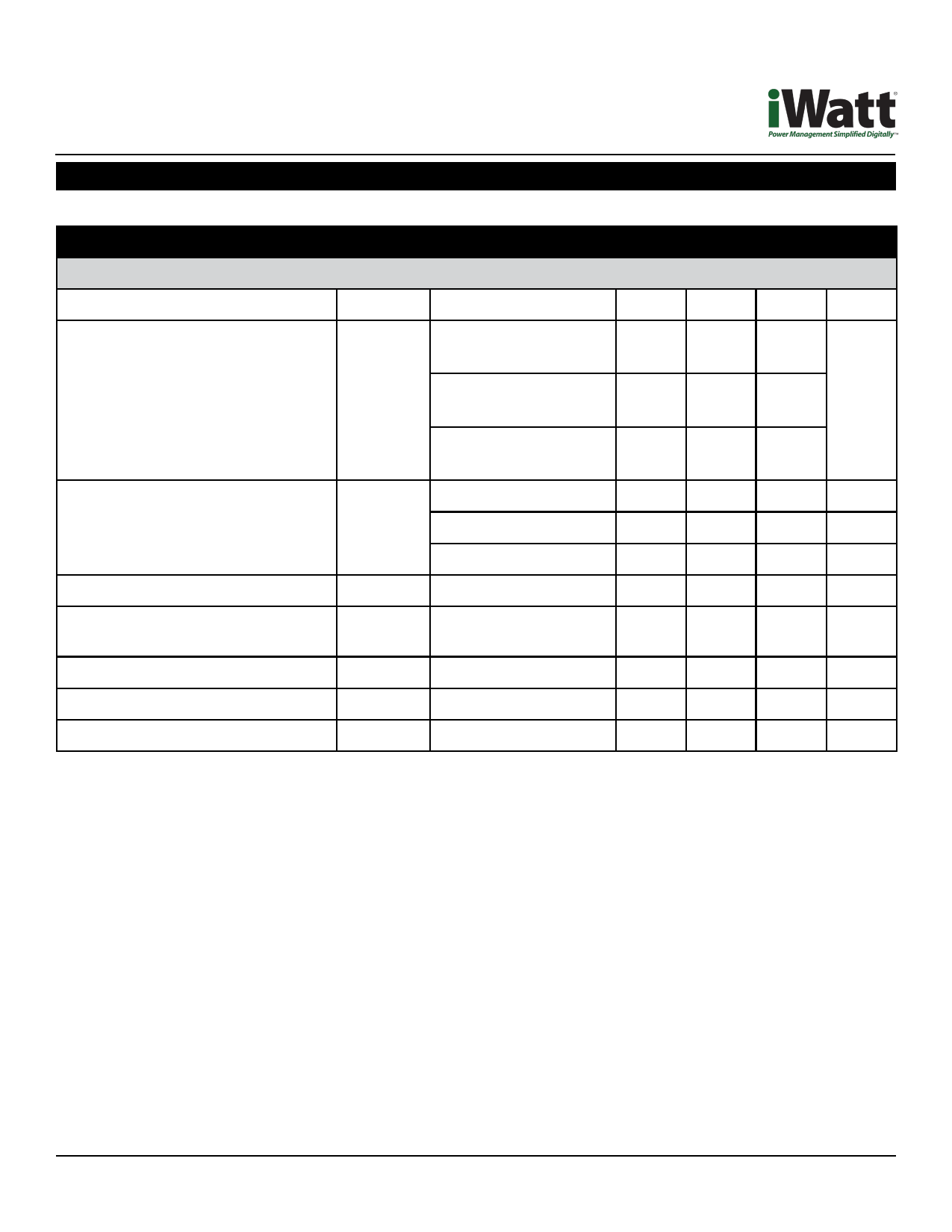

7.0 Electrical Characteristics (cont.)

VCC = 12V, -40°C ≤ TA ≤ +85°C

Parameter

BJT Section (Pin 1, Pin 2, and Pin 8)

Collector cutoff current

Symbol

ICB0

Test Conditions

VCB = 800V, IE = 0A

VCE = 800V, REB = 0Ω TA

= 25°C

Collector-Emitter cutoff current

ICES

VCE = 800V, REB = 0Ω TA

= 100°C

VCE = 500V, REB = 0Ω TA

= 25°C

DC Current Gain2

Collector-Base breakdown voltage

Collector-Emitter breakdown voltage

(Emitter and base shorted together)

hFE

VCB0

VCES

VCE = 5V, IC = 0.2A

VCE = 5V, IC = 0.3A

VCE = 5V, IC = 1mA

IC = 0.1mA

IC = 1mA, REB = 0Ω

Collector-Emitter sustain voltage

Collector-Emitter saturation voltage2

PWM switching frequency

VCEO(SUS)

VCE sat

fSW

IC = 1mA, LM = 25mH

IC = 0.1A, IB = 0.02 A

> 50% load

Min

15

10

10

800

800

500

Typ Max Unit

0.01 mA

0.01

0.02 mA

0.005

40

30

V

V

V

0.1 0.3

V

64 kHz

Notes:

1. These parameters are not 100% tested, guaranteed by design and characterization.

2. Impulse tP ≤ 300μs, duty cycle ≤ 2%

3. Operating frequency varies based on the load conditions, see Section 10.6 for more details.

Rev. 1.2

iW1810

April 6, 2012

Page 5

5 Page

iW1810

Off-Line Digital Green-Mode PWM Controller

Integrated with Power BJT

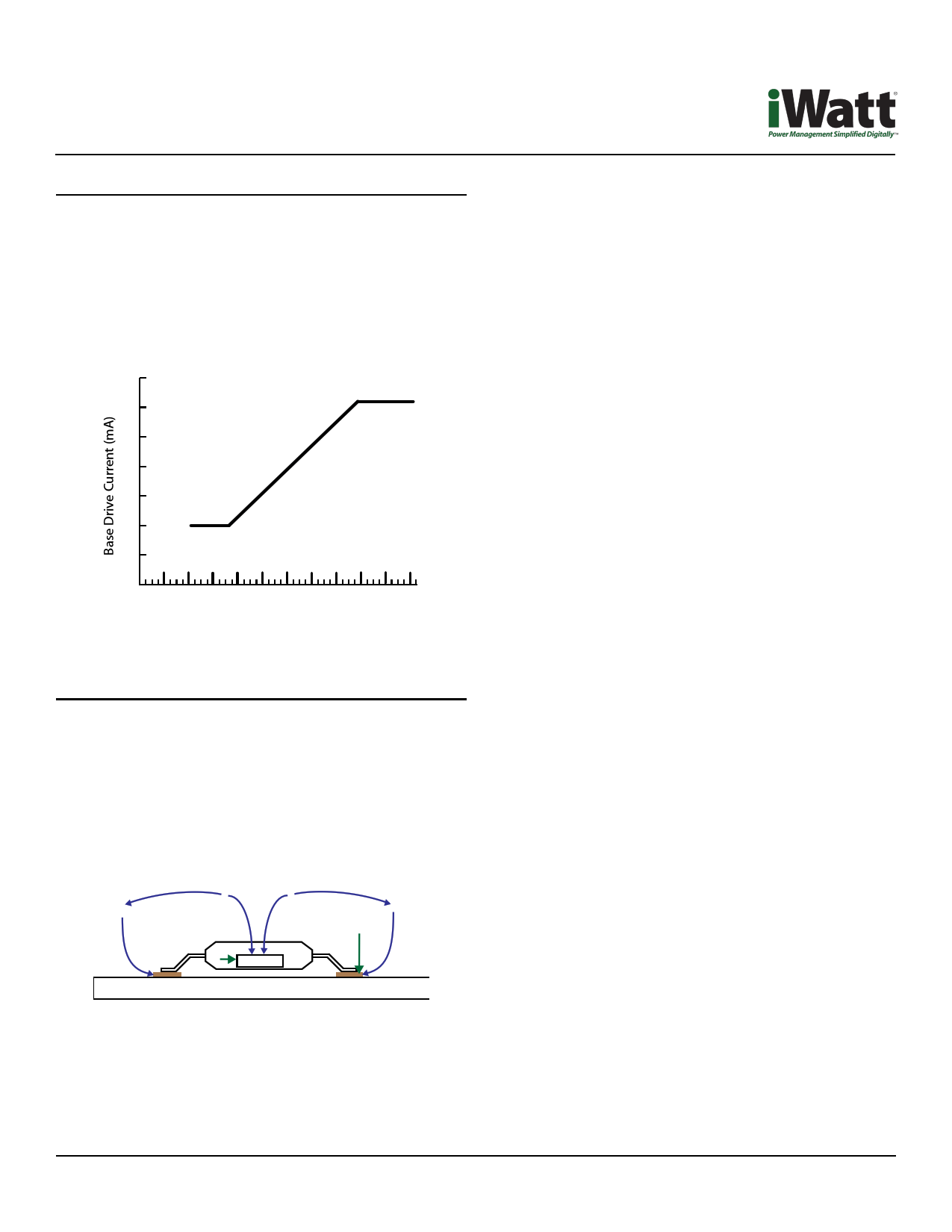

10.11 Dynamic Base Current Control

One important feature of the iW1810 is that it directly drives

an internal BJT switching device with dynamic base current

control to optimize performance. The BJT base current

ranges from 10mA to 31mA, and is dynamically controlled

according to the power supply load change. The higher the

output power, the higher the base current. Specifically, the

base current is related to VIPK, as shown in Figure 10.5.

35

30

25

20

15

10

5

00 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1

VIPK (V)

Figure 10.5: Base Drive Current vs. VIPK

10.12 Thermal Design

The iW1810 may be installed inside a small enclosure,

where space and air volumes are constrained. Under these

circumstances θJA (thermal resistance, junction to ambient)

measurements do not provide useful information for this

type of application. Hence we have also provided ψJB which

estimates the increase in die junction temperature relative to

the PCB surface temperature. Figure 10.6 shows the PCB

surface temperature is measured at the IC’s GND pin pad.

used to estimate the maximum junction temperature. For

a typical 3-W power supply, the power dissipation can be

around 500mW.

The output power table in Section 3.0 recommends

maximum practical continuous output power level be

achieved under the following conditions:

●● Typical 5V-output power supply designs with a Schottky

rectifier diode

●● Ambient temperature of 50°C for open frame and

adapter enclosure internal temperature of 60°C in a non-

ventilated environment

●● AC Input voltage is 85VAC at 47Hz

●● Minimum bulk capacitor voltage is 90V for open frame

and 70V for adapter

●● The iW1810 device is mounted on PCB with no special

enhancement for heatsinking and the emitter pin

temperature is kept below 90°C

Under a given power dissipation, reducing the GND,

emitter, and collector pin temperature reduces the junction

temperature. Generally, increasing the PCB area and

associated amount of copper trace reduces the junction

temperature. In particular, the power BJT is a power source

and therefore the PCB plating area attached to the two

collector pins and the emitter pin can be reasonably large to

gain the thermal benefits without violating the high voltage

creepage requirements if higher output power is desired.

Higher output power is also achievable if bulk capacitor

voltage is higher, design is for high line only, design

components temperature restriction limit is higher, ambient

temperature is lower, or extra metal piece/heat spreader is

attached to related pins or package.

BJT collector

ψJ-BJT

J

Collector pin

TJ

J ψJB

B

IC Die

PCB Top Copper Trace

GND pin

Printed Circuit Board

Note: For illustrative purposes only does not represent a correct pinout or size of chip

Figure 10.6: Thermal Resistance

The actual IC power dissipation is related to the power supply

application circuit, component selection, and operation

conditions. The maximum IC power dissipation should be

Rev. 1.2

iW1810

April 6, 2012

Page 11

11 Page | ||

| Páginas | Total 13 Páginas | |

| PDF Descargar | [ Datasheet IW1810.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| IW1810 | Off-Line Digital Green-Mode PWM Controller | iWatt |

| IW1812 | Off-Line Digital Green-Mode PWM Controller | Dialog Semiconductor |

| IW1816 | Off-Line Digital Green-Mode PWM Controller | Dialog Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |